Autonomy in Agriculture – where does the AEF fit? – AEF Meetings in Milwaukee

Autonomy in Agriculture Day, the AEF and AEM Ag Technology Leadership Group examine how to collaborate and take on the challenges of autonomous machine to machine interoperability. A packed agenda saw several potential collaborations explored. The Team Leaders discussed activities that the AEF should support to take on the challenges of a multi branded autonomous system. How can AEF ensure that machine to machine communication will be safe, secure and have defined liability?

Association of Equipment Manufacturers (AEM) hosted these meetings and presented on the continued efforts in collaboration and standardization of autonomous machines. The AEM represents over 1000 members and 200+ machinery product lines globally and support standardization through ISO Standards as the preferred approach on global products. AEM membership represents a significant partner for ISO standards development and will offer technical experts to collaborate on consensus automation standards. The goal is to promote consistency across the off-road sectors of Agriculture, Mining, and Construction. AEM members have already completed work on 9 different ISO standards relating to automation and this will be a great resource for future AEF efforts.

As an example of how an industry might collaborate on such an undertaking that includes global operations and international standards, the AEF met with Joel Haight. Ph.D. Professor Haight teaches Industrial Engineering at the University of Pittsburgh and is involved with The National Institute for Occupational Safety and Health (NIOSH). Specifically discussed was the 62-member partnership focused on Mine Automation and Emerging Technologies Health and Safety. This partnership addresses issues pertaining to the health and safety implications of automation and emerging technologies in mining operations. The purpose of this group is to promote collaboration between the mining industry, equipment manufacturers, labor, consensus standards groups, government researchers and regulators and academic researchers. The goal is seeking a safe transition to a more automated mining industry. The strategy and tactics employed by NIOSH are a perfect model for AEF to follow as we take on a similar set of tasks.

There is a need to develop standards that cover the multiple domains and AEF has found a partner in this effort in CEMA. Ivo Hostens of CEMA presented on this partnership and how the AEF AgIN standards can help. CEMA focuses on several priorities. Mostly through the participation in selected EU projects and initiatives, CEMA contributes to driving innovation in the agri-food chain. The European farm equipment industry is a leading technology provider for farmers worldwide and is part of the solution to feed a growing world population. CEMA is helping to map the legislative environment in Europe while defining the digital processes that enable data flow and interoperability on IoT platforms. Using a practical approach to the complexity of these issues it is possible to develop international standards. The message is clear that a highly structured collaboration is needed, and AEF will participate.

Erik Pekkeriet from Wageningen University presented his experience with robotics and Precision Ag 2.0. AEF was presented the work being done in the Netherlands around Precision Ag 2.0 and smart farming processes. The studies conducted in 2019-2020 found 203 farms in the Netherlands using at least one Precision Ag 2.0 process with most of the functionalities being Variable Rate Application (VRA) based. The Precision Ag 2.0 has 3 basic actions on the farm that drive improved results. By acquiring data, using the FMIS to process the data one can then use regional decision models to implement the most efficient precision ag functions. This data and model generate a prescription plan for machinery prepared for VRA. AEF certified ISOBUS tractors and implements with precision actuators are then used for the VRA per the prescription plan. All these mentioned activities currently happen while the machinery is operated in person, on location.

How can we take this work from supervised to unsupervised?

Robots… Robots are the future, Robots can reach every plant, every animal, everywhere to act more frequently and collect reproducible data. Robots are proven to perform well in repetitive short cycle tasks and act with more precision at the right time. Can we create a Multi branded sensor, data, AI algorithms, machines and robots combined as one eco-system? This autonomy can reduce Soil compaction, chemicals, water, fertilizers/manure, energy, labor, administration, risks, logistics. It can also continuously handle rough working conditions and will scale easier to feed our growing communities.

The challenges to date include poor implementation and validation, limited durable examples in open field and poor connectivity with limited implement support. No international standards are complete to help plan, simulate, execute, secure data and learn/improve by software. These new machines will have limited remote assistance and safety concerns as well. The AEF has the expertise and vision to tackle these challenges with practical solutions. How does the industry give the controls to the farmer? The stakeholders on the farm need to be sure that the data is safe, secured and that machines have plug and play connectivity that is vendor independent.

Sound familiar?

The AEF regards interoperability as a key function, and we will support the industry in this way as autonomy and robotics are brought into the field globally.

AEF and Wageningen University and Research are collaborating on agROBOfood. agROBOfood is the European Union’s Horizon 2020 project dedicated to accelerating the digital transformation of the European agri-food sector through the adoption of robotic technologies. The aim of the project is to consolidate, extend and strengthen the current ecosystem by establishing a sustainable network of Digital Innovation Hubs (DIH), boosting the uptake of robotic solutions by the agri-food sector. The agROBOfood Consortium has 39 partners, including AEF, led by Wageningen University & Research.

Also presenting was the organization Global Org. for Agricultural Robots (GOFAR). The GOFAR mission is focusing on promoting and developing Agricultural Robots worldwide. AEF hopes to use a FIRA event to promote more collaboration. FIRA has organized a series of trade shows and technical conferences at many global locations for this promotion. By partnering with GOFAR, the FIRA show group should organize some events with AEF and AEF will bring the machinery experts to lead discussions.

Over a full day of presentations and roundtable discussion it was clear that AEF has much work to do for the industry. The collaboration between AEM, AEF member companies and outside organizations will be key to the industry success and the future possibility of autonomous machinery moving unsupervised through a farm.

High-Speed ISOBUS at AETC in Louisville, KY

At this year's Agricultural Equipment Technology Conference (AETC) in Louisville, Kentucky, the AEF presented High Speed ISOBUS (HSI) to a wider…

Review Grüne Woche in Berlin, Germany

For the third time, AEF has participated in the “Grüne Woche” fair in Berlin, Germany, from January 17-26, 2025.

AEF Machine Plugfest planned for TIM and WIC

The AEF is organizing a Machine Plugfest at DEULA in Warendorf, Germany. From June 10 to 13, 2025.

High-Speed ISOBUS at AETC in Louisville, KY

At this year's Agricultural Equipment Technology Conference (AETC) in Louisville, Kentucky, the AEF presented High Speed ISOBUS (HSI) to a wider…

Review Grüne Woche in Berlin, Germany

For the third time, AEF has participated in the “Grüne Woche” fair in Berlin, Germany, from January 17-26, 2025.

AEF Machine Plugfest planned for TIM and WIC

The AEF is organizing a Machine Plugfest at DEULA in Warendorf, Germany. From June 10 to 13, 2025.

Review AEF TechWeek in Munich, Germany

AEF Tech Week, held from January 21 to 23, 2025, at Panasonic in Munich, was a significant event, fostering collaboration and innovation within the…

AEF presented at AED Summit 2025

On January 15, 2025, Austin Gellings, AEMs Senior Director of Ag and General Manager Norbert Schlingmann introduced AEF at the Associated Equipment…

AEF Steering Committee and Team Leaders met in Frankfurt at VDMA

The AEF Steering Committee, as well as AEF Team Leaders and Deputies met at VDMA in Frankfurt beginning of December for three days. On the first day,…

AgGateway Annual conference: November 11 – 13, 2024 in Austin, Texas

General Manager Norbert Schlingmann was a speaker at the AgGateway Annual meeting in Austin, Tx, USA on Nov 12, 2024. The presentation included…

Successful AEF presence at EIMA in Bologna, Italy

AEF is delighted to share the highlights of the participation in EIMA International 2024, from November 6 - 10. This trade show saw an exceptional…

Review FIRA USA Conference: October 22 – 24, 2024 in Woodland, California

From October 22 – 24, 2024, the FIRA USA event took place at the Yolo County Fairgrounds in Woodland California. The three-day event pulled together…

AEF Topics at the VDI LAND.TECHNIK Conference: November 6 – 7, 2024 in Osnabrück, Germany

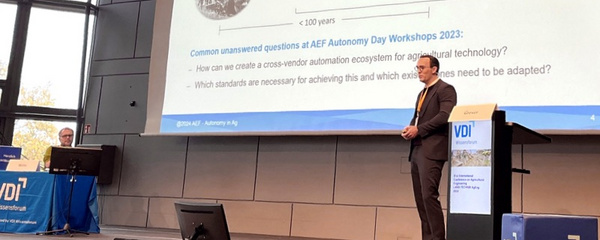

This year, the VDI International Conference on Agricultural Engineering LAND.TECHNIK, one of the most renowned events for the community of…

The AEF Tech Week 2025 at Panasonic in Munich

The registration for the upcoming TechWeek is still open. Please take a few minutes to register. Register before 11 January 11, 2025 and pay 250 EUR,…

Announcement AEF Spring Plugfest in Milwaukee, Wisconsin, US

We are pleased to announce the next AEF Spring Plugfest. It will take place from March 31 to April 3, 2025 in Milwaukee, the largest city in the state…

Upcoming events 2025

Grüne Woche, AEF Tech Week, AEF Spring Plugfest, AEF Machine Plugfest, AEF Fall Plugfest

Car2Car Forum in Frankfurt

The Car2Car Communication Consortium organised the annual forum at the House of Logistics and Mobility (HOLM) in Frankfurt am Main, Germany on October…

Review Plugfest

The AEF European Plugfest 2024 took place from September 16 to 20 at the Savoia Regency Hotel in Bologna, marking the fourth time this successful…

AEF Chair Group re-elected during General Assembly in Bologna

At its recent General Assembly meeting in Bologna, Italy, the Agricultural Industry Electronics Foundation (AEF) re-elected Andrew Olliver, Digital…

News from AEM: Interoperability in Action to Improve Farming Operations Worldwide

The Agriculture Industry Electronics Foundation (AEF)’s largest-ever Plugfest was buzzing with excitement as new connections and combinations were…

High Speed ISOBUS (HSI) Discovery Station

At the AEF Fall PlugFest 2024, the HSI Team hosted its 6th “Discovery Station” event – so named because the team is researching and experimenting (aka…

Digital Camera Testing during Fall Plugfest in Bologna

During this year’s AEF Fall Plugfest 2024 in Bologna the Digital Camera System (DCS) team took the chance to test cameras and monitors from AEF member…

Review AEF Communication and Marketing (CM) summer activities in North America

The AEF CM Team recently had the opportunity to speak at two conferences in the US. AgIN and TIM were presented to demonstrate how AEF is dedicated to…

Exciting Changes Ahead: The New Online SUT Editor is available

At the AEF Fall Plugfest 2024, an important announcement was made regarding the transition to the new Online SUT Editor. This new editor will…

AgIN at AEF Plugfest: Networking in a great community!

The AgIN (Agricultural Interoperability Network) team met at this year’s AEF Fall Plugfest in Bologna.

The Latest from Autonomy in Ag

Considering the rapid development of autonomous technology, the Autonomy in Ag (AUT) project is becoming a central force within the AEF in addressing…

AEF at EIMA 2024

We are excited to announce that the AEF will be present at the EIMA trade fair in Bologna, Italy, from 6-10 November 2024. Visit us at Hall 37, Stand…

AUX-O to be removed from AEF Conformance Tests

The AEF will be discontinuing support for the AUX-O ISOBUS functionality. For several years there have been two different conformance tests for…

AEF toward the future – Webinar organized by Federunacoma

The webinar “AEF toward the future” was organized by FederUnacoma and held in the morning of July 1st with the purpose to introduce the new AEF…

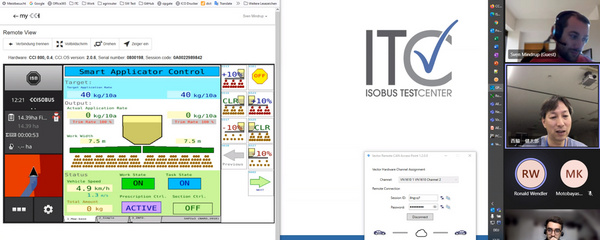

AEF and ISO met together in Tokyo

In June 2024, the AEF and ISO TC23 SC19 organized a full week of meetings in conjunction with the Japanese Agricultural Machinery Manufacturers…

Review of successful AEF Information Day in Tokyo

The AEF kicked off the Information Day in Tokyo, Japan with great support from JAMMA on the local organization!

Autonomy in Ag – Planting seeds towards an interoperable, autonomous future

The overall goal of AEFs project “Autonomy in Ag” is to face the current challenges of autonomous machines with standards and technologies for…

AEF participated in the Celebration of Modern Agriculture on the National Mall in Washington DC

On May 6th-8th 2024 the AEF was invited to participate in the Celebration of Modern Agriculture on the National Mall in Washington DC.

AEF 2024 Fall Plugfest in Bologna, Italy

The next European Plugfest will take place from September 16 to 20, 2024 in Bologna, Italy at the Savoia Hotel. This will be the fourth time at this…

Upcoming events 2024

AEF Fall Plugfest, VDI International Conference on Agricultural Engineering LAND.TECHNIK, EIMA

AEF starts new project called Autonomy in Ag (AUT)

The AEF Steering Committee approved the project charter and the wish to start engagement in autonomy. The goal of the new “Autonomy in Ag” (AUT)…

AEF Steering Committee and Team Leaders met in St. Valentin, Austria at CNH plant

The AEF Steering Committee, as well as AEF Team Leaders and Deputies met at CNH in St. Valentin, Austria for three days.

Announcement Ag on the mall

The Future of Food & Farming

The Agricultural Industry Electronics Foundation (AEF) will exhibit at the "Celebration of Modern Agriculture on the…

High-Speed ISOBUS (HSI) meeting during Plugfest week

The week from February 26 to March 1, 2024 was for the HSI experts packed with meetings in a room far from the exhibit floor, first with ISO meetings…

AEF Project INFO – What’s that?

The INFO project is driven by three main use cases: What are the capabilities of my machine? What is the right product (e.g. a baler) for the…

DCS Team: Welcome Dennis Schäfer, new Deputy Team Lead

Three month after the Kick-off meeting, the AEF is pleased to announce that the DCS Team has a deputy: Dennis Schäfer.

Updated AEF 005 Guideline

The AEF Guideline “AEF 005 ISOBUS Alignment of ISOBUS systems with ISO 25119” has been released as RIG 3.

Upcoming events 2024

Ag on the Mall, ASABE AIM, AEF Fall Plugfest, VDI International Conference on Agricultural Engineering LAND.TECHNIK, EIMA, ...

Review from the AEF 2024 Spring Plugfest in Houston, TX

From February 27 – March 1, 2024 the AEF North American Plugfest was held in Houston Texas.

Invitation for AEF Information Day in Tokyo at JAMMA - Monday, June 17, 2024 in Tokyo, Japan

The Agricultural Industry Electronics Foundation (AEF), a global non-profit organization founded to improve cross-manufacturer compatibility in…

AEF wins AE50 award for Agricultural Interoperability Network

The Agricultural Industry Electronics Foundation (AEF), was recognized by the American Society of Agricultural and Biological Engineers (ASABE) with a…

AEF sponsored ASABE AETC conference

On February 12-14 the AEF was a sponsor of the Agricultural Equipment Technology Conference (AETC) 2024.

AEF participates in the International Agricultural Autonomy Symposium

On Thursday 08 February 2024, the first International Agricultural Autonomy Symposium took place as part of the schedule of events at the World FIRA…

AgIN met in Kaiserslautern, on January 24-25, 2024

The Agricultural Interoperability Network (AgIN) project team made its debut in 2024, rapidly resuming work after winter break without significant…

Green Week in Berlin 2024

Panel discussion about agricultural dataspaces and Artificial Intelligence during the Green Week in Berlin on January 25, 2024.

AEF participating WORLD FIRA 2024

The leading international event for agricultural robotics and autonomous solutions will open its eighth edition from 6 to 8 February at the…

AEF Tech Talks in February and March

The AEF started scheduling a new educational series called Tech Talks on a monthly basis in 2020. AEF Tech Talks are short, condensed introductions to…

Registration for Spring Plugfest in Houston will be open December 15, 2024

Houston, a major city in Texas will be the destination of the next AEF Plugfest again in conjunction with Commodity Classicom. Setting up the George…

Review: Autonomy Day

Autonomy in Agriculture – where does the AEF fit? This was the title for the second AEF Autonomy Day which was held on November 29 at the FederUnacoma…

Trade show review: Agritechnica

AGRITECHNICA - The world's leading trade fair for agricultural machinery took place from November 12 to 18 at the Hannover Messe showgrounds. AEF was…

Review: Presentations at Agritechnica

Wireless infield Communication – Road Safety

Wireless in-field communication (WIC) serves as a crucial facilitator for seamless and interoperable…

10 years of Conformance Test

AEF celebrates 10th anniversary of ISOBUS Conformance Test and Database

With the AEF ISOBUS Database, AEF has been ensuring transparency of ISOBUS…

New AEF Project team: Digital Camera Systems

A few weeks ago, the AEF kicked off the new project team Digital Camera Systems or DCS for short. More than 25 participants from various AEF member…

AEF ISOBUS Certified label

One of the first tasks after the founding of the AEF was to make ISOBUS (ISO 11783) easier to understand for the whole industry. This led to the…

Web based trainings

AEF member companies enjoy complimentary access to our web-based training courses. These instructional videos cover technical fundamentals across…

Upcoming events 2024

Green Week, ASABE Agricultural Equipment Technology Conference (AETC), AEF Plugfests ...

AEF offering reduced membership fee to new members

The leadership at AEF decided after 2021 to offer a reduction of the AEF membership fee to interested companies that may be considering involvement in…

AEF starts AgIN as Data Space Initiative

What is "AgIN"? The Agricultural Interoperabilty Network [AgIN] is a dataspace that provides a framework to foster collaboration between agricultural…

Trade show preview: Agritechnica

AEF Booth at Agritechnica

As in previous years, the AEF will also be present with a booth at Agritechnica in Hannover (Germany) this year.…

Presentations at the VDI conference AgEng

The LAND.TECHNIK International Conference on Agricultural Engineering is the official opening event of AGRITECHNICA. During the two day conference…

Nominated for the DLG Agrifuture Concept Winner 2023

The Agricultural Interoperability Network (AgIN) has been selected on the shortlist for the DLG-Agrifuture Concept Winner 2023, for pioneering…

Nominated for the Systems & Components Trophy 2023

AEF’s “Enhanced Road safety for agricultural vehicles" is a nominee of the a SYSTEMS & COMPONENTS TROPHY – Engineers‘ Choice 2023.

CEMA summit

The AEF participated in the Innovation Village which showed high-tech innovative agricultural equipment during a summit organized by the European Ag…

Review: AEF Fall Plugfest – Antibes

From the September 18 – 22, 2023 the AEF European Plugfest took place in Antibes, France at the Juan-les-Pins Conference Centre.

Review JWG 16 at IVT Expo, Chicago

iVT Technology Expo Chicago is a growing heavy vehicle engineering conference held annually in the US the last week of August. The technology expo…

Changes in AEF Teams

In recent months, the AgIN Team has accelerated work to build an interoperability network for the agricultural industry. Several subgroups were formed…

Nebraska Tractor Test Lab (NTTL) 103 Year Celebration

The University of Nebraska Tractor Test Lab celebrated its century of testing tractors on July 8, 2023 on the east campus. A representation of tested…

ASABE AIM in Omaha, NE, USA

The ASABE’s Annual International Meeting took place from July 9 – 12 in Omaha, Nebraska.

AEF Fall Plugfest – Antibes

In just a few weeks, from September 18 to 22, 2023, the next AEF Fall Plugfest will take place at Congress Center of Antibes Juan-les-Pins, France,…

Thank you Anita Sennett

On the 22nd of June 2023 Anita Sennett, the AEF Secretary attended (and documented) her last AEF Steering Committee meeting before commencing her…

New AEF staff: Birgit Wagner

The AEF is very happy to welcome Birgit Wagner as a new member of the AEF team, based in Gütersloh, Germany.

Upcoming Fall Plugfest: Antibes, France - September 18 to 22, 2023

Planning for the next AEF Fall Plugfest is already underway. After a successful Plugfest in North America in March this year, the next European…

General Manager presented AgIN during VDI conference “Smart Farming”

“What is the Agricultural Interoperable Network” was the title of Norbert Schlingmann’s presentation during the VDI conference “Smart Farming” on…

High-Speed ISOBUS presented on Industrial Ethernet Week Panel

In March 2023 the AEF was invited to participate as HARTING connector company hosted its annual discussion regarding the advancements of industrial…

Can All Your Farm Equipment Speak the Same Language?

Due to having AEF Plugfest at the Commodity Classic trade show, AEF has had several opportunities to grow our media coverage in North America. These…

Review: Spring Plugfest 2023 in Orlando was back in conjunction with the Commodity Classic

The annual AEF North American Plugfest was back at the Commodity Classic in 2023.

AETC Conference in Frenso, CA

On February 12-14 the AEF was a sponsor of the Agricultural Equipment Technology Conference (AETC) 2023. This annual event is hosted by the American…

AEF at World Fira 2023 in Toulouse

From the 7th to the 9th of February the 7th World FIRA took place at the AGROBIOPOLE, just south of Toulouse in France. This new three day format…

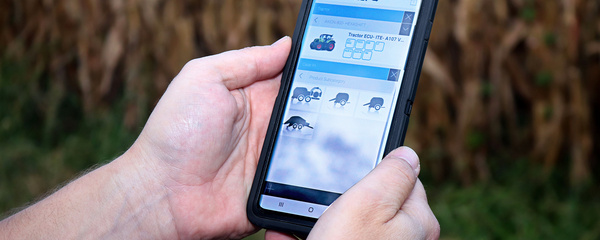

New Tractor Implement Management (TIM) Landingpage

The AEF TIM functionality, launched in 2019, is the first functionality using a standardized, certified communication between tractor and implement.…

New AEF staff: Marcel Urban

The AEF is very happy to welcome Marcel Urban as a new member of the AEF team, based in Gütersloh, Germany.

AEF Tech Week 2023 in Wageningen

The AEF teams consist of volunteers coming from our member companies who engage for AEF beside their regular job. To successfully work on projects…

AEF appoints new Chair Group

AEF Board Sets Focus on Collaboration, Plugfest Electrified by Record Attendance.

At its recent General Assembly meeting in Bologna, Italy, the…

Review AEF Fall Plugfest

Successful Plugfest is back on stage in Europe after the North American one in New Orleans in March 2022. More than 330 participants enjoyed the…

Thank you Peter van der Vlugt

Peter has been a member of the AEF Steering Committee since the beginning and was elected as Vice-Chairman in 2008. Then as Rainer Hofmann stepped…

Thank you Rainer Hofmann and Peter Hieronymus

AEF thanks Rainer and Peter for their active engagement and wishes a well-deserved retirement.

Jan-Hendrik Wölker left AEF

Jan-Hendrik Wölker has left AEF as of end of October to pursue other interests. He started in 2012 working for the company Fuhrhop & Partner…

AEF Tech Week, Wageningen, January 2023

AEF has grown, even during the last couple of years, and with that growth comes the challenge of effective collaboration between the many teams. All…

UT3 launch planned in Q1 – 2023

The AEF Project Team UT3 has been working on the next generation of the AEF Conformance Test for Universal Terminal UT3. Already in use during the…

Announcement AEF Spring Plugfest Orlando March 2023

Orlando, a major city dedicated to amusement! In central Florida you will find a destination packed with amusement parks and world renowned family…

Review SIMA Show

After a long break due to the Covid pandemic, the postponed SIMA show took place in Paris Nord - Villepinte / France from November 6 through 10 2022.…

Review EIMA Show

From the 9th to the 13th of November the 45th EIMA show took place in Bologna, Italy. The record number of 327,100 visitors certainly enjoyed the…

Industrial Vehicle Technology Expo USA

iVT Technology Expo Chicago was the first time this show was held in the US. The technology expo focuses on bringing together component manufacturers…

Upcoming events 2022 / 2023

AgEng-LAND.TECHNIK, International Green Week, Tech Week, AETC Conference , AEF Plugfests 2023

AEF Fall Plugfest – Planning underway

In just a few weeks, from October 17 to 21, the next AEF Fall Plugfest will take place at the Savoia Hotel in Bologna, Italy. We are very much looking…

Autonomy in Agriculture – where does the AEF fit? – AEF Meetings in Milwaukee

Autonomy in Agriculture Day, the AEF and AEM Ag Technology Leadership Group examine how to collaborate and take on the challenges of autonomous…

AEF at ASABE Annual International Meeting (AIM)

After two years of virtual events, the ASABE’s Annual International Meeting returned to an “in person” event which took place from the 17th to the…

AEF Taskdata Validator

Operators working with the TaskController in the field sometimes have issues while importing ISO-XML taskdata in different terminals. This could be…

Team Lead Positions Changed

AEF is pleased to announce that Ryan Milligan has been approved as AEF Team Lead Deputy of the Communications and Marketing Team (C&M) and happy to…

New Released Guidelines

Guideline AEF 007 RIG 2.0 ISOBUS – ISOBUS Automation

The Functional Safety Team has successfully released a new version of the Guideline AEF 007 that…

AEF Autonomous Agriculture Day - Milwaukee, June 9

Autonomy in Agriculture Day, the AEF and AEM Ag Technology Leadership Group examine how to collaborate and take on the challenges of autonomous…

AEF Makes History with Next Generation, High-Speed ISOBUS Demonstration

Next generation ISOBUS is roughly 4,000 times faster than the original ISOBUS technology.

Review: Spring Plugfest 2022 in New Orleans in conjunction with Commodity Classic

After the cancellations of the last few Plugfests due to the pandemic, this was the first face to face AEF Plugfest since September 2019.

AEF at ‘Ag On The Mall’ event

The Agricultural Industry Electronics Foundation (AEF) has exhibited at the "Celebration of Modern Agriculture on the National Mall" event in…

ASABE/ AETC

Last month on February 12-14 the AEF was a sponsor of the Agricultural Equipment Technology Conference (AETC) 2022.

Common project AgGateway and AEF: Data Link

In March 2021, AgGateway and the AEF signed a Memorandum of Understanding to collaborate on initiatives to increase the seamless exchange of…

UT3 - Looking for member support in Acceptance Testing

The AEF Project Team Universal Terminal UT3 is currently working on the development of the next generation of the UT Conformance Test. This new…

Second High Speed ISOBUS guideline published as Released International Guideline (RIG)

A subgroup of physical layer experts from the High Speed ISOBUS team (HSI) created AEF RIG 042 “High Speed Implement Bus – Physical layer – PHY and…

Registration deadline extended by 4 days to the 22nd of Feb and becomes a hybrid event

Our wish is, and has always been, that engineers attend the plugfest in person however due to the continuing COVID situation and the variation in…

AgGateway annual conference: November 8-10, 2021, Nashville, Tennessee

AEF Vice-Chair Andrew Olliver and General Manager Norbert Schlingmann, were speakers at the AgGateway Annual meeting in Nashville, Tennessee, USA on…

EIMA 2021 show review

AEF was present at the EIMA 2021 show in Bologna with a booth in cooperation with REI and FederUnacoma. Information about AEF products were provided,…

Become a sponsor for AEF Spring Plugfest now

The preparations for the AEF Spring Plugfest in New Orleans, which will take place from March 9 to 11, 2022 are already in full swing.

New AEF Project Teams

AEF is pleased to introduce two new projects to its members: Task Controller 2 and Agricultural Interoperability Network.

Guideline AEF 041 RIG 1.0

High Speed Implement Bus – Physical Layer – Communication channel and breakaway connectors published

AEF Introduces ISOBUS Database App for Mobile Convenience

Ag equipment dealers, manufacturers, farmers to easily view ISOBUS compatible products across brands

AEF Steering Committee Meeting

On the 22nd and 23rd of September the AEF Steering Committee held a face to face meeting in the centre of Frankfurt. Apart from the regular monthly…

AEF General Assembly 2021

The 2021 AEF General Assembly took place in the afternoon of the 23rd of September and, just like the 2020 edition, was another virtual event, the…

AEF Virtual Plugfest

Due to the Covid-19 pandemic, no physical AEF Plugfest events could take place. This encouraged the AEF, in cooperation with Vector Informatik, to…

AEF offering reduced membership fee to new members

Most people have become tired of all the bad news we hear every day. It has been a difficult time for everyone. The leadership at AEF thought it would…

Data Management Update - New ideas for Standards for Transport operations

The AEF Data Management team is looking into additional use cases for transport operations. But some important elements are still missing. The…

TC-GEO Conformance Test FMIS

In 2017 the AEF released the TC-BAS Conformance Test for FMIS. With the upcoming release 2021R2, planned for the 1st of November, the AEF Conformance…

AEF at the EIMA 2021 show

The next EIMA, an International Agricultural and Gardening Machinery Exhibition takes place from October 19 thru 23, 2021 in Bologna, Italy.

AEF ends working relationship with CertTech

After 11 years of a long and effective collaboration, it was decided to end the relationship as of September 30, 2021. This collaboration had a long…

Team Lead position changed

Communication & Marketing – Thank you Andrew Olliver and welcome Alfred Kornes and Klaus-Herbert Rolf

AEF Fall Plugfest 2021 canceled – Virtual Plugfest planned!

Due to on-going concern over the spread of coronavirus (COVID-19) and related travel restrictions, the AEF decided to cancel the 2021 Fall Plugfest…

Change in John Deere Steering Committee member

Jürgen Hollstein will retire end of July this year and will be succeeded by Stefan Stahlmecke as new representative from John Deere.

Team Lead Positions Changed - Thank you Peter Münch and welcome Johannes Lange and Christian Jungkind

Peter Münch has left his AEF team leader position in June this year. Since the beginning of the AEF, he has been in charge of the functional safety…

Team Lead Positions Changed - New Deputy for Data Management: Jason Roesbeke

AEF is very pleased to introduce Jason Roesbeke from CNH Industrial, based in Bruges, Belgium as another Deputy Team Lead for the Expert Team Data…

AEF ISOBUS Database – Even More Improvements!

Following on from last summer’s updates and thanks to the continual feedback from the AEF Service Council, the Database Service team have been hard at…

Data Management Update

FMIS Conformance Test

As with all conformance tests and certified compatibility our goal in the end is satisfied customers.

In today's agricultural…

Wireless-Infield-Communication field test

In April 2021, the AEF organized a proof of concept to demonstrate the latest developments in Wireless-Infield-Communication together with the…

Support for AEF Security Team needed

The AEF Security Team is looking for expertise from AEF companies in the following areas:

New AEF member: MC Elettronica S.r.l.

MC Elettronica is a company specializing in design of sensors and “high tech” electronic components for agricultural machines, dedicated to PRECISION…

New AEF member: Agricon GmbH

Agricon is a full-service provider for precision farming solutions. It offers a wide range of products dedicated to improve crop production from the…

New AEF Member: Neways Electronics International N.V.

Neways Electronics International N.V. is active in the international EMS (Electronic Manufacturing Services) market. As System Innovator and life…

New AEF Member: ImageLine

Image Line is an Italian company – included in Italian official registry for innovative SMEs – that develops softwares, web portals and databases for…

New AEF Member: ifm group of companies

When it comes to pioneering automation and digitization technology, the ifm group of companies is your ideal partner. Since its foundation in 1969 ifm…

Thank you Mark Benishek

AEF secretary Mark Benishek retired end of last year and was succeeded by Anita Sennett representing the Association of Equipment Manufacturers (AEM)…

AEF changed organisation structure with the start of 2021

As announced during the virtual AEF General Assembly in October 2020 by Peter Hieronymus, a dedicated team of seasoned AEF members was tasked with…

Plugfest 2021 planning underway, Stuttgart, Germany

AEF announces plans are underway for the next Plugfest in Stuttgart, Germany. The dates are set for September 20 to 24, 2021. We are excited at the…

FederUnacoma Round Table: ISOBUS Interoperability

FederUnacoma, the Italian Association of Ag. Machine Manufacturers, has always taken an active role in supporting the AEF through the years. Although…

High Speed ISOBUS (HSI) Demonstration at AGRITECHNICA 2021 – Support Needed!

Exactly 20 years ago at Agritechnica 2001 the first ISOBUS systems were demonstrated with the Universal Terminal application (even though the first…

AEF and ISOBUS articles created for N.A. digital forum

During 2020 the AEF Communications and Marketing North American Sub Group worked on a group of sponsored articles that ran on the Precision Farming…

ISOBUS Conformance Testing for Resale Value and Compatibility

With so many different manufacturers creating a wide scope of agricultural products available on the market today, this is a fairly common problem for…

An Essential Resource: the AEF ISOBUS Database

Whether you are a salesperson or service tech, the ISOBUS Database will become an essential part of your toolbox. It provides important ISOBUS…

Eight of the Most Compatible ISOBUS Functionalities for Precision Farming

In a market offering so many different tractors and implements, how can you make the right choice? Now more than ever, when considering the precision…

Plugfests, ISOBUS and Project Teams: the AEF Tackles Tough Ag Industry Issues

Every day, farm tractors and implements are connected together and the electrical connectors are engaged.

Plugfest: An Event for Friends and Competitors

How do you get a group of ag software engineers excited? Most engineers have similar traits. They want to provide new and better designs, and the best…

Introducing TIM — a Farmer’s New Best Friend

Tractor Implement Management, or what we call “TIM,” is a cross-product and cross-manufacturer ISOBUS solution where the implement controls certain…

The Three Things You Need to Know About M2M

M2M, also known as “Machine-to-Machine Communication,” is exactly what it sounds like. It stands for two machines “communicating” together.

New Security Team Lead: Bradley Nielsen

AEF is very happy to present the new Security Team Lead: Bradley Nielsen from CNH Industrial, based in Burr Ridge, Illinois, agreed to take over the…

New Deputy for Wireless Infield Communication team: Tobias Nothdurft

AEF is happy to present the new WIC Deputy Team Lead: Tobias Nothdurft from AGCO, based in Marktoberdorf, Germany, agreed to take over the tasks from…

New AEF Member: Materna

Materna is a full service provider in the premium segment successfully implementing IT projects for the industry sector, business customers and the…

New AEF Member: Junkkari Oy

Junkkari Oy is a family owned company located in Finland, established over 60 years ago and is part of the MSK Group Oy.

AEF and AgGateway align to deliver digital solutions for Agriculture

AgGateway and the Agricultural Industry Electronics Foundation (AEF) have signed a Memorandum of Understanding to collaborate on initiatives to…

AEF General Assembly

The first ever virtual AEF General Assembly took place on Thursday the 15th of October. The AEF Chairperson, Peter van der Vlugt opened the meeting…

Thank you Marcello Mongiardo

As mentioned above, during this year’s Chair Group (CG) election meeting resulted in a change of the Vice-Chairperson. Marcello Mongiardo as the…

Core Membership changes and additions

Core Membership changes

At the last AEF General Assembly held October 15, 2020, leadership addressed a change request to the Core membership. The…

AEF Tech Talks

In 2020 the AEF started scheduling a new educational series called Tech Talks on a monthly basis. AEF Tech Talks are short condensed introductions to…

EIMA Digital preview

On November the 11th and 12th the AEF had the honour of presenting two sessions during the EIMA Digital Preview (EDP). The EDP was a purely online…

Service Council review

On 28th of October 2020 the third AEF Service Council took place in Warendorf, Germany. The event – aimed at dealer service and sales staff as well as…

Project Universal Terminal (UT 3) ramps up in 2020

Project activities for the UT 3 ISOBUS functionality conformance test have received much interest for the past few years. In January 2020 a face to…

Open position for Security Team Leader

A new lead is sought for the AEF Security Expert Team. This is a diverse team made up of security professionals from both OEMs and security…

AEF ISOBUS Database – Improvements

The latest version of the AEF ISOBUS Database was released in the middle of summer and included the highly anticipated changes to the Product Upload…

ATLAS - High Level Architecture

Τhe overall goal of the Horizon 2020 project “ATLAS” is the development of an open digital Network through which information and services become…

Attention all users of the AEF ISOBUS Conformance Test!

The current AEF Conformance Test environment was developed based on a now outdated version of National Instruments TestStand. (To be precise we are…

WIC presentation at ASABE Annual International Meeting (AIM)

Once again, the AEF were presenting at the 2020 ASABE Annual International Meeting (AIM). The event took place from the 13th to the 15th of July and,…

AEF at AGROSALON

The AGROSALON took place from the 6th to the 9th of October in Moscow and thanks to the grateful assistance of the Agriculture Engineering team at…

AEF to present at EIMA Digital Preview

The Covid-19 emergency has defined a new economic and social geography with global restrictions. The international trade shows worldwide have been…

ATLAS - What are the use cases?

Smart agricultural machines, sensors and data processing services have assisted farmers by providing an abundance of information that help optimize…

![[Translate to deutsch:] [Translate to deutsch:]](/fileadmin/_processed_/6/b/csm_news-aef-fallback-xl_64b6f87913.jpg)

Der Conformance Test zur Selbstdurchführung - Fragen und Antworten

Seit Beginn dieses Jahres können Hersteller den AEF Conformance Test unter Berücksichtigung definierter AEF Regeln selbst durchführen und die…

Introduction to the new team - PT13 Security

Last year in October a new AEF team was formed, composed of security experts from several AEF member companies. Norbert Schlingmann, General Manager…

Update on High Speed ISOBUS

Following on from the very successful High Speed ISOBUS presentation given at the Landtechnik conference in November last year, this edition of the…

AEF Plugfests in 2020

Aufgrund der Corona-Virus Pandemie (COVID-19) müssen derzeit alle sozialen Kontakte eingeschränkt und größere Menschenansammlungen vermieden werden.…

New guideline for Extended Farm Management Information Systems Data Interface (EFDI) available

This EFDI guideline provides an extensible communication system concept and defines rules for adding new functionalities to cover specific use cases…

Maschinen- und Sensorhersteller im EU-Projekt ATLAS: Umfragen zu technischen Anforderungen an eine datengesteuerte Landwirtschaft

Die europäische Union finanziert im Rahmen des EU – Förderprogramm „Horizion 2020“ das Projekt ATLAS. Das Ziel dieses Projektes ist die Entwicklung…

First TIM products are present in the AEF ISOBUS Database

Since AEF’s development of the Tractor Implement Management (TIM) was launched in December 2019, the first products supporting the TIM functionality…

![[Translate to deutsch:] [Translate to deutsch:]](/fileadmin/_processed_/3/e/csm_news-AEF-TIM-Award_ccbe792038.jpg)

TIM mit AE50 Award und Davidson Prize in den USA ausgezeichnet

Die AEF wurde im Februar für ihre herausragende Entwicklung des Tractor Implement Management (TIM) gleich zweimal ausgezeichnet. Zunächst überreichte…

AEF Core Membership changes

As well as the recently announced AEF membership changes involving Kubota Corporation and Kverneland Group, the start of 2020 has ushered in one more…

agROBO food - AEF with CEMA participation

In parallel to ATLAS, AEF is a partner in a second EU funded project named agROBOfood.

ISOBUS Seminar at REI

The ISOBUS event held in Reggio Emilia (Italy) on December 13th 2019 titled “Agriculture looks to the future” was a great success.

AEF, AETC and ISOBUS; A Great Combination

Last month on February 10-12 the AEF was a sponsor of the Agricultural Equipment Technology Conference (AETC) 2020. This annual event is hosted every…

New PT05 Lead Jasper Jeninga

As of December 1, 2019, the AEF has a new project team leader for the ISOBUS Automation Group: Jasper Jeninga, Team Leader at CLAAS based in Bad…

New PT04 Deputy Ronny Preußer

The AEF is happy to introduce Ronny Preußer as new deputy team lead for project team Service & Diagnostics.

Hara Spathi started as Project Manager for ATLAS

Since February, 12, 2020 Hara Spathi has joined the AEF as project manager for the ATLAS program. ATLAS focuses on the standardization of data…

AEF received ASABE AE50 award for Tractor-Implement-Management

Mark Benishek AEF Secretary, General Manager Norbert Schlingmann and Chairman Peter van der Vlugt received the AE50 award during the ASABE…

Kubota Corporation to take over AEF core membership from Kverneland Group

After 11 years of Kverneland Group’s direct engagement as AEF founding - and core member, the mother company Kubota Corporation has taken over the AEF…

Engineering First TIM products certified

After the successful release and roll out of the AEF TIM conformance test some days ago to certification test laboratories, we are happy to announce…

AEF auf der Agritechnica 2019

Die Agritechnica 2019 fand vom 10. bis 16. November in Hannover statt. Auch in diesem Jahr war die AEF mit einem Stand in Halle 15 vertreten. Dabei…

AEF Speeches at VDI conference 2019

The AEF was well represented with three different presentations at the 77th Landtechnik AgEng Conference which took place on Friday the 8th and…

TIM gewinnt AE50-Preis 2020

Die AEF freut sich, einen der begehrten „AE50“-Preise 2020 der American Society of Agricultural and Biological Engineers (ASABE) für die Entwicklung…

![[Translate to deutsch:] [Translate to deutsch:]](/fileadmin/_processed_/4/9/csm_news-atlas_bc3a915654.jpg)

ATLAS fokussiert die Standardisierung von Schnittstellen in der datenbasierten Landwirtschaft

Beim Projekt „Agricultural Interoperability and Analysis System (ATLAS)“ arbeiten führende Landtechnikhersteller gemeinsam mit Verbänden, Unternehmen…

Further development of the AEF ISOBUS Database

Which implement can be operated with the tractor’s ISOBUS terminal? Which functionalities are supported by the combination of vehicles? Can the farmer…

AEF at ACPA

From the 14th to the 17th of October the Asian-Australasian Conference on Precision Agriculture took place at the Punjab Agricultural University in…

Russian Federation is interested in ISOBUS technology

Last October 2019, Norbert Schlingmann, AEF General Manager, was invited to speak at a conference in Moscow entitled “Universal control and monitoring…

TPPL – Twisted Pair Physical Layer

In January 2019, the 3rd revision of ISO 11783 – Part 2: Physical Layer has been published. As you may know this part of the ISO standard details the…

The guiding hand behind TIM - Hans Jürgen Nissen

As with all projects, at some point they come to completion. This is true with the project, Tractor Implement Management (TIM), which was released…

Neuer Besucherrekord beim AEF Plugfest

Vom 17. bis 19. September fand im neuen Konferenzzentrum im französischen Antibes Juan-Les-Pins das europäische AEF Plugfest statt. Mit Unterstützung…

AEF Conference Day: Partnering with others in Digital Landscape

In addition to the Plugfest event, project team meetings and the AEF General Assembly, the AEF Conference event took place in the afternoon of…

Opportunity in Digital Farming – Lead for EU subsidized project team

The AEF is looking for a project team lead to help with an EU subsidized design project. The benefits of digital farming are increasing day by day and…

AEF at InfoAg 2019

Once again the AEF was present at Union Station in St Louis, Missouri participating in the 2019 edition of InfoAg. As with previous years the AEF…

AEF Conformance Test: Preiserhöhung ab Januar 2020

Ab Januar 2020 erhöht sich die Jahresgebühr, die Hersteller für den AEF Conformance Test zahlen müssen, auf 24.300 Euro für die Flat-Rate-Lizenz, auf…

AEF Steering Committee und Teamleiter zu Gast bei SDF

In der letzten Juniwoche trafen sich das Steering Committee, die Leiter der Projektteams und ihre Stellvertreter im bayerischen Lauingen zu einer…

TIM – die zukunftsweisende Kommunikation zwischen Traktor und Anbaugerät

TIM (Tractor Implement Management) ist eine produkt- und herstellerübergreifende ISOBUS Lösung, bei der das Arbeitsgerät bestimmte Traktorfunktionen…

![[Translate to deutsch:] [Translate to deutsch:]](/fileadmin/_processed_/6/b/csm_news-aef-fallback-xl_64b6f87913.jpg)

Zweites AEF Service Council im Oktober

Ende Dezember 2018 fand das erste AEF Service Council in Warendorf statt. Aufgrund des positiven Verlaufes äußerten die Teilnehmer den Wunsch, die…

New AEF Member: Proemion GmbH

We are a technology company that builds connectivity solutions for machines. We provide the infrastructure to connect mobile machines with the cloud…

New AEF Member: Parker Hannifin Mfg Finland Oy

Parker Hannifin is a Fortune 250 global leader in motion and control technologies. For more than 100 years the company has engineered the success of…

AEF Events at the Plugfest

In conjunction with the Plugfest, you will have the option of seeing the Plugfest activities in action or particpate in a number of conference &…

![[Translate to deutsch:] [Translate to deutsch:]](/fileadmin/_processed_/6/b/csm_news-aef-fallback-xl_64b6f87913.jpg)

VDI Workshop zum Thema ISOBUS und TIM

Unter dem Titel „ISOBUS Automation using TIM“ fand am 28. Juni im Berliner Mercure Hotel MOA ein internationaler VDI Workshop statt. Für die AEF war…

AEF activity at the ASABE Annual International Meeting

AEF Sponsored and exhibited at the 2019 Annual International Meetings of the ASABE in Boston, Massachusetts, USA on July 7 – 10, 2019. The focus of…

![[Translate to deutsch:] [Translate to deutsch:]](/fileadmin/_processed_/4/e/csm_news-Holten_5dbca3a840.jpg)

Dank an Martijn Holten

Martijn Holten verließ im Juni Kverneland Mechatronics und damit auch die Position als Stellvertreter des Projektteams Service & Diagnostics (PT4),…

Dank an Harald Dietel

Seit der Startsitzung am 16. März 2011 in Frankfurt am Main hat Harald Dietel das Projektteam High Voltage (PT7) als Teamleiter maßgeblich…

Mark von Bibra: neuer Projektmanager bei der AEF

Seit dem 24. Juni 2019 verstärkt Mark von Bibra als Projektmanager die AEF. Der Australier hat in Melbourne und Singapur studiert und in den letzten…

![[Translate to deutsch:] [Translate to deutsch:]](/fileadmin/_processed_/6/b/csm_news-aef-fallback-xl_64b6f87913.jpg)

Internetseite und AEF Web Based Training in Französisch

Passend zum AEF Fall Plugfest in Frankreich im September werden die AEF Internetseite und die drei Module des AEF Web Based Training in französischer…

![[Translate to deutsch:] [Translate to deutsch:]](/fileadmin/_processed_/4/f/csm_2-AEF-Plugfest_96ec2ab16b.jpg)

AEF Fall Plugfest: Jetzt Sponsor werden

Vom 16. bis zum 20. September findet im französischen Antibes das AEF Fall Plugfest 2019 statt. Seien Sie dabei, wenn sich ein fachkundiges Publikum…

![[Translate to deutsch:] [Translate to deutsch:]](/fileadmin/_processed_/f/7/csm_6-AEF-Plugfest_d0fab48cc0.jpg)

AEF Fall Plugfest: Jetzt registrieren

Die Vorbereitungen für das AEF Plugfest vom 17. bis zum 20. September im französischen Antibes laufen auf Hochtouren.

![[Translate to deutsch:] [Translate to deutsch:]](/fileadmin/_processed_/5/b/csm_news-medium-voltage_24ddf55d63.jpg)

Neues Projektteam: Medium Voltage

Am 26. September 2018 trafen sich Experten aus mehreren AEF Mitgliedsunternehmen, um das neue Projektteam Medium Voltage (PT12) zu starten. Nachdem…

![[Translate to deutsch:] [Translate to deutsch:]](/fileadmin/_processed_/6/b/csm_news-aef-fallback-xl_64b6f87913.jpg)

Händler-Registrierung und AEF Ticket-System

Auch die Händler-Registrierung erfährt eine Neuerung. So können sich Händler zukünftig selber in der AEF ISOBUS Datenbank registrieren und einloggen.…

![[Translate to deutsch:] [Translate to deutsch:]](/fileadmin/_processed_/b/d/csm_news-conformance_7c536031b0.jpg)

AEF Compatibility Check

Anwender können sich mithilfe der AEF ISOBUS Datenbank über ISOBUS Funktionalitäten informieren, die sowohl vom einzelnen Produkt als auch von…

![[Translate to deutsch:] [Translate to deutsch:]](/fileadmin/_processed_/d/c/csm_news-AEF-ISOBUS-Database_239fb05c8b.jpg)

Weiterentwicklungen der AEF ISOBUS Datenbank

Hersteller können ab September 2019 den AEF Conformance Test unter Berücksichtigung definierter AEF Regeln selbst durchführen, um ihren Kunden höchste…

New AEF Member: Panasonic Industry Europe

Panasonic Industry Europe GmbH is part of the global Panasonic Group and provides industrial products and services in Europe.

![[Translate to deutsch:] [Translate to deutsch:]](/fileadmin/_processed_/2/4/csm_news-special-training__1f5850b556.jpg)

Spezielle Trainingsmodule für AEF Mitglieder

Was ist ISOBUS? Wie funktioniert die AEF ISOBUS Datenbank? Welche Vorteile hat das AEF ISOBUS CheckTool? Diese und weitere Fragen beantworten die…

![[Translate to deutsch:] [Translate to deutsch:]](/fileadmin/_processed_/6/b/csm_news-aef-fallback-xl_64b6f87913.jpg)

Neue Zwei-Draht-verbindung für ISOBUS

Das AEF Projektteam „Engineering & Implementation“ hat den Einsatz einer Zweidraht-Verbindung (TPPL – Twisted Pair Physical Layer) für ISOBUS Systeme…

Zertifizierung für Zulieferer

Elektronik und Software-Zulieferer entwickeln ihre ISOBUS Steuergeräte (ECU) für mehrere Hersteller (OEM-Partner). Diese Steuergeräte sind in der…

New AEF Member: Orion Tecnologia e Sistemas Agrícolas Ltda

Orion Tecnologia e Sistemas Agrícolas Ltda is an innovative Brazilian company that designs and manufactures special spraying implements for installing…

New AEF Member: J.ASSY Agricultural

J.Assy Agricultural specializes in technology solutions for agribusiness. They are one of Brazil’s largest investors in R & D in this industry.

Rückblick: SIMA 2019 in Paris

Vom 24. bis 28. Februar fand die 78. Ausgabe der SIMA im Messezentrum Paris-Nord Villepinte statt. In diesem Jahr konnten die Veranstalter 232.000…

Rückblick: AXEMA Technical Conference

Am 23. Februar fand im Vorfeld der SIMA 2019 in Paris die dritte „AXEMA Technical Conference“ statt. Während in den umliegenden Messehallen die…

Rückblick: AEF auf der AETC

Vom 11. bis 13. Februar 2019 fand in Louisville, Kentucky, die „Agricultural Equipment Technology Conference“ (AETC) statt, auf der die AEF ebenfalls…

![[Translate to deutsch:] [Translate to deutsch:]](/fileadmin/_processed_/0/a/csm_3-AEF-Plugfest_02e73593b0.jpg)

Jetzt Sponsor für AEF Spring Plugfest werden

Die Vorbereitungen für das AEF Plugfest im Frühjahr, das vom 7. bis zum 9. Mai im amerikanischen Lincoln (Nebraska) stattfindet, laufen bereits auf…

![[Translate to deutsch:] [Translate to deutsch:]](/fileadmin/_processed_/6/b/csm_news-aef-fallback-xl_64b6f87913.jpg)

Rückblick: AEF Service Council in Warendorf

Am 19. Dezember 2018 fand in Warendorf das erste AEF Service Council statt. Im Mittelpunkt der Veranstaltung, die sich an Mitarbeiter aus dem Service…

![[Translate to deutsch:] [Translate to deutsch:]](/fileadmin/_processed_/6/b/csm_news-aef-fallback-xl_64b6f87913.jpg)

Im Video: Carsten Hühne zum AEF Ticket-System

Welche Aufgabe hat das AEF Ticktet-System? Wie funktioniert es? Welche Rolle spielt es im Kontext mit den Diagnosemöglichkeiten der AEF ISOBUS…

Ankündigung: AEF auf der SIMA 2019

Vom 24. bis zum 28. Februar findet im Messezentrum Paris-Nord Villepinte die 78. SIMA statt, die internationale Leitmesse für Landwirtschaft und…

TIM: Vorteile und Ziele

TIM (auf Deutsch: Traktor-Geräte-Management oder Gerät-steuert-Traktor) ist eine produkt- und herstellerübergreifende ISOBUS Lösung der…

![[Translate to deutsch:] [Translate to deutsch:]](/fileadmin/_processed_/6/4/csm_news-database_d82dd887b1.jpg)

Service Council zum Thema AEF Ticketsystem und Datenbank-Diagnose

Das AEF Ticketsystem ist wesentlicher Bestandteil der AEF ISOBUS Datenbank. Mithilfe dieses Ticketsystems lassen sich Informationen über…

New AEF Member: HELUKABEL

Established in Germany in 1978, HELUKABEL® is one of the world’s leading cable manufacturers and suppliers. In addition to our production sites in…

![[Translate to deutsch:] [Translate to deutsch:]](/fileadmin/_processed_/5/2/csm_news-database-hardware_cc6237a8d9.jpg)

Neue Login-Seite der AEF-ISOBUS-Datenbank

Die AEF freut sich, dass die neue Login-Seite der AEF ISOBUS Datenbank online gestellt wurde.

New AEF Member: Dacom

Dacom provides growers and the agribusiness sector with data-driven advisory services throughout the world. Using intelligent analyses, all available…

Rückblick: EIMA in Italien

Vom 07. bis zum 11.November 2018 fand die Messe EIMA International in Bologna, Italien, statt. Mehr als 315.000 Besucher aus 150 Ländern nahmen dieses…

Präsentation: AEF Geschäftsführer bei Jahresversammlung der AgGateway

Der Geschäftsführer der AEF, Norbert Schlingmann, nahm als Hauptredner an der Jahresversammlung von AgGateway in Austin, Texas, am 13. November 2018…

Pilotprojekt: Sicherheit im Straßenverkehr erfolgreich für Landmaschinen getestet

Die AEF hat zusammen mit dem ETSI-Komitee, zuständig für Maschine-zu-Maschine- Kommunikation, ein Pilotprojekt entwickelt, das dafür sorgen soll, dass…

Dank an Jaap van Bergeijk

Jaap van Bergeijk wird zum Ende des Jahres seine Teamleiterposition aufgeben. Seit Beginn der AEF hat er das Team Conformance Testing geleitet und…

![[Translate to deutsch:] [Translate to deutsch:]](/fileadmin/_processed_/5/b/csm_news-medium-voltage_24ddf55d63.jpg)

Neues Projektteam Medium Voltage

Am 26. September haben sich Experten aus mehreren AEF Unternehmen zusammengesetzt, um das neue Projektteam PT12 – Medium Voltage – zu starten.…

Rückblick: TIM Plugfest in Bologna

Das achte TIM Plugfest fand am 19. und 20. September im Hotel Savoia Regency in Bologna statt. Es war das erste Mal, dass ein TIM-spezifisches…

Rückblick: AEF feierte 10-jähriges Jubiläum

Am 19. September feierte die AEF ihr 10-jähriges Bestehen im italienischen Bologna mit einer ereignisreichen Veranstaltung – parallel zum AEF Fall…

![[Translate to deutsch:] [Translate to deutsch:]](/fileadmin/_processed_/2/0/csm_AEF-PIC-PlugfestBologna2018-0008_89747e280d.jpg)

Rückblick: AEF Fall Plugfest in Bologna

Vom 18. bis 20. September fand im Savoia Regency Hotel in Bologna das diesjährige Herbst-Plugfest statt.

AEF Plugfest zusammen mit TIM Plugfest und Feierlichkeiten zum 10. Jubiläum

Das 8. TIM Plugfest wird am 19. und 20. September im Rahmen des europäischen AEF Plugfests im Savoia Hotel Regency, Bologna, Italien veranstalt. AEF…

![[Translate to deutsch:] [Translate to deutsch:]](/fileadmin/_processed_/f/7/csm_news-ag-gateway_8787accb74.jpg)

AEF ist jetzt Mitglied bei AgGateway

Beide Organisationen sind daran interessiert, optimale Produkte für den Landwirt zu entwickeln. Um Funktionalitäten von landwirtschaftlichen Geräten…

![[Translate to deutsch:] [Translate to deutsch:]](/fileadmin/_processed_/2/5/csm_news-multiva_50503dda88.jpg)

Neues AEF-Mitglied: Multiva

Multiva steht als Marke für qualitativ hochwertige Landmaschinen, die von der Firma Dometal Oy mit Sitz in Loimaa, Finnland, hergestellt werden. Unser…

![[Translate to deutsch:] [Translate to deutsch:]](/fileadmin/_processed_/e/e/csm_news-geo_dded5505f3.jpg)

Neues AEF Mitglied: Geoprospectors

Geoprospectors ist ein führender Anbieter von Bodensensorik in den Bereichen Präzisionslandwirtschaft, Subsurface Engineering und luftgestützte…

Neu: AEF ISOBUS Funktionalität ISB

Die Funktion ISB bzw. die entsprechende ISOBUS Shortcut-Taste bezieht sich auf eine physische Taste (einen Schlüssel oder Schalter) in der…

Rückblick: Frühlings-Plugfest in Lincoln, Nebraska

Das Frühlings-Plugfest fand diesmal vom 15. bis 17. Mai in Lincoln, Nebraska statt. Das Hotel Embassy Suites war gemeinsam mit dem NTTL Testinstitut…

![[Translate to deutsch:] [Translate to deutsch:]](/fileadmin/_processed_/d/b/csm_news-aef10years_de10bde107.jpg)

2008 bis 2018: AEF feiert zehnjähriges Jubiläum

Sieben internationale Hersteller von landwirtschaftlichen Geräten und zwei Verbände gründeten am 28. Oktober 2008 die Agricultural Industry…

![[Translate to deutsch:] [Translate to deutsch:]](/fileadmin/_processed_/0/a/csm_3-AEF-Plugfest_02e73593b0.jpg)

Jetzt anmelden: Plugfest in Lincoln

Vom 14. bis 18. Mai findet in Lincoln Nebraska das Plugfest statt. Eine Anmeldung ist ab sofort möglich.

Rückblick: Commodity Classic

Die Commodity Classic Ag Messe in Nord-Amerika fand in diesem Jahr vom 27. Februar bis 1. März in Anaheim, Kalifornien statt.

AEF will join the AEM booth during the Commodity Classic show, February 27 – March 1 in Anaheim, California USA

Commodity Classic is America's top agricultural convention and trade show, managed by farmers, for farmers. The trade show connects cutting-edge…

AEF at Agritechnica in Mid-November

Again the AEF will be present at Agritechnica in Hannover, Germany running from November 12th through 18th.